https://sparksafeltp.co.uk/news-item/the-essential-connections/

The Essential Connections

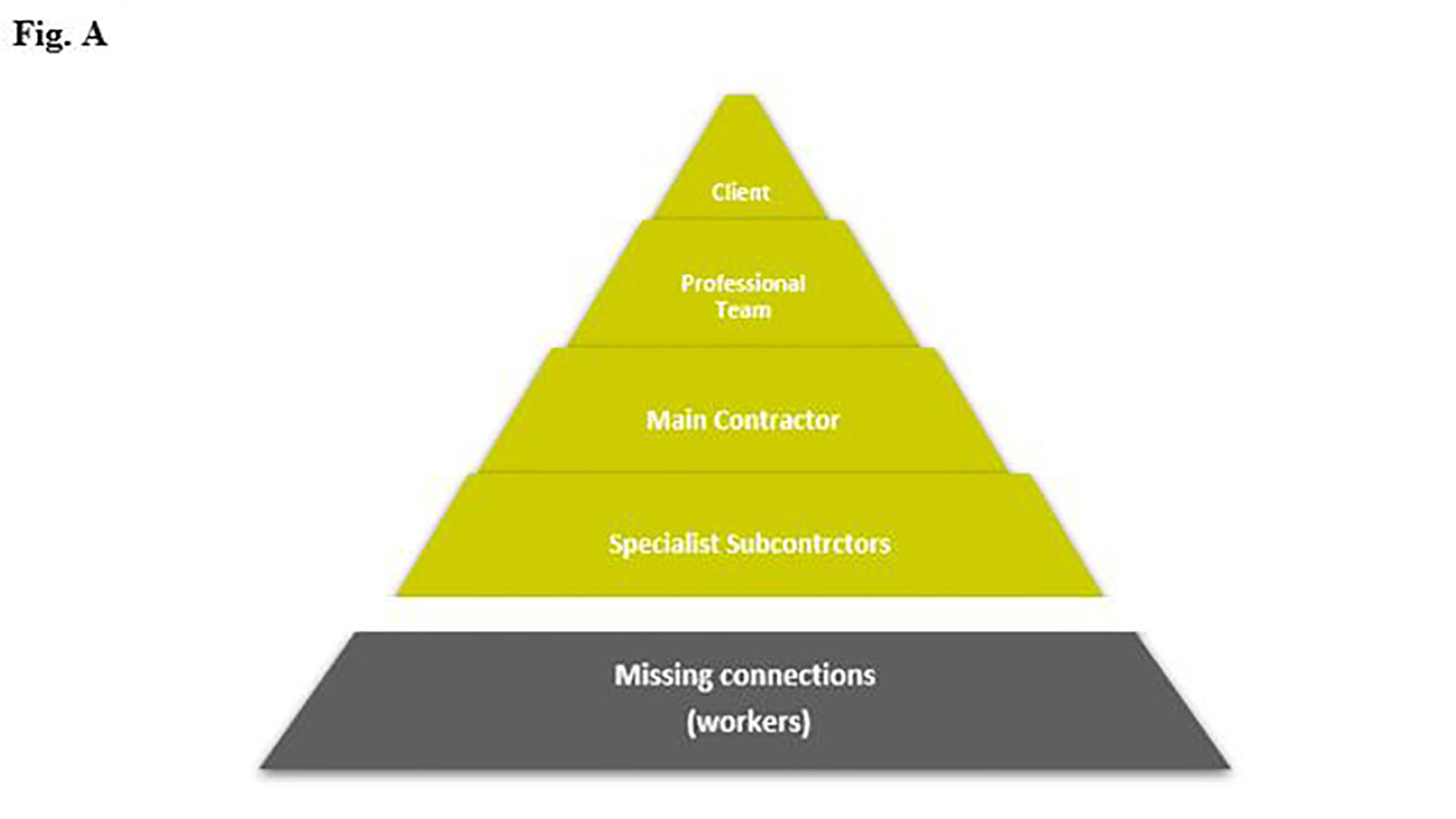

The conventional Client procurement model of large-scale construction projects in the UK, is usually headed by a professional team comprising of an architect, consultant engineers, surveyors, and other specialists.

Following a separate pre-qualification and tendering exercise, the next leading party in the project management hierarchy is the main contractor who is engaged to oversee and coordinate the construction phase of the project.

Positioned below the main contractor are the mechanical and electrical subcontractors along with a host of other large and small specialist service providers.

There are many variances to the model in Fig. A, which are determined by how the project is funded. Private finance initiatives, for example, can bring about an exchange in the relationship and positioning of the parties.

The Missing Connections

The following questions often determine the measure of success for a project from the Client perspective –

None of the above can be achieved without the efforts of “the missing connections.” For too long, construction procurement has overlooked the vital role and impact of construction workers. The relationship described under “the essential connections” are corporate, the connections are financial and legal with little or no provision made for the occupational identity and role of skilled workers.

The absence of such provision has contributed to the deficiency in the competency and productivity of electrical contracting and most of the other building service sectors. Consequently, the UK construction industry is becoming increasingly dependent on semi-skilled, under-qualified and unqualified electrical workers.

Possession of a Health and Safety plastic card by a worker provides access to the site, it ticks the box for the gatekeepers, but often masks the individual and workforce competency offered by an electrical contractor’s extended supply chain of subbies.

Most parties above the level of specialist subcontractors in Fig. A, are conditioned by established convention and necessity to focus on programming, design and financial outcomes.

Tracking and auditing how workforce competency is matched to the requirements of the project, typically attract negligible activity beyond the initial site induction procedure.

The absence of a connected system, i.e., one that provides on-line visibility between the parties (top to bottom and worker to Client), has masked the melting iceberg of specialist competencies on which the construction industry depends.

The industry, its Clients and workers are deeply interdependent. Current projects are threatened by a diminishing pool of qualified and skilled workers. Future projects can expect to be subject to further increased difficulties as the supply chain weakens through low uptake of authentic apprenticeship training and the impact of national demographic trends.

Time for Connections

Ignorance is not bliss. Knowing exactly who is on your project and how well qualified they are to perform tasks on your behalf is vital. The initial site induction approach under CDM regulations is not enough. Site induction procedures are like a “selfie,” providing cursory scrutiny only of a worker’s occupational identity and qualifications on the day of entry to the project.

Fixation on the safety element of a worker’s credentials has obscured the occupational trade credentials on almost every UK project.

Test your Connections

What is the percentage of fully qualified, up to date electricians presently working on your project?

A model has emerged which relies on one or two go-to qualified workers overseeing large squads of unqualified or under-qualified electrical workers. The focus on safety passports has brought about unintended negative consequences. We need to change the model by restoring and rebuilding occupational identity, individual visibility and supply accountability.

We need to connect Clients with workers. The benefits of doing so, produce drivers that incentivise upskilling of existing workers and the recruitment of apprentices leading to improvements in quality, productivity, safety and value for money outcomes.