https://sparksafeltp.co.uk/news-item/considering-pgn-01-16-and-the-sparksafe-workforce-composition-report/

The Department of Finance has produced guidance for Client project managers, main contractors and electrical contractors covering the subject of the Workforce Composition Report (WCR). This guidance can be found on Pg. 15 – 17 of PGN 01/16 under Section 7- Make-up of the Electrical Workforce.

Electrical installation, maintenance and repair work in the building services industry is delivered across a wide spectrum of construction projects. The scope, environment, value and programme demand of a project, are just some of the key considerations in determining the composition and application of electrical labour resources.

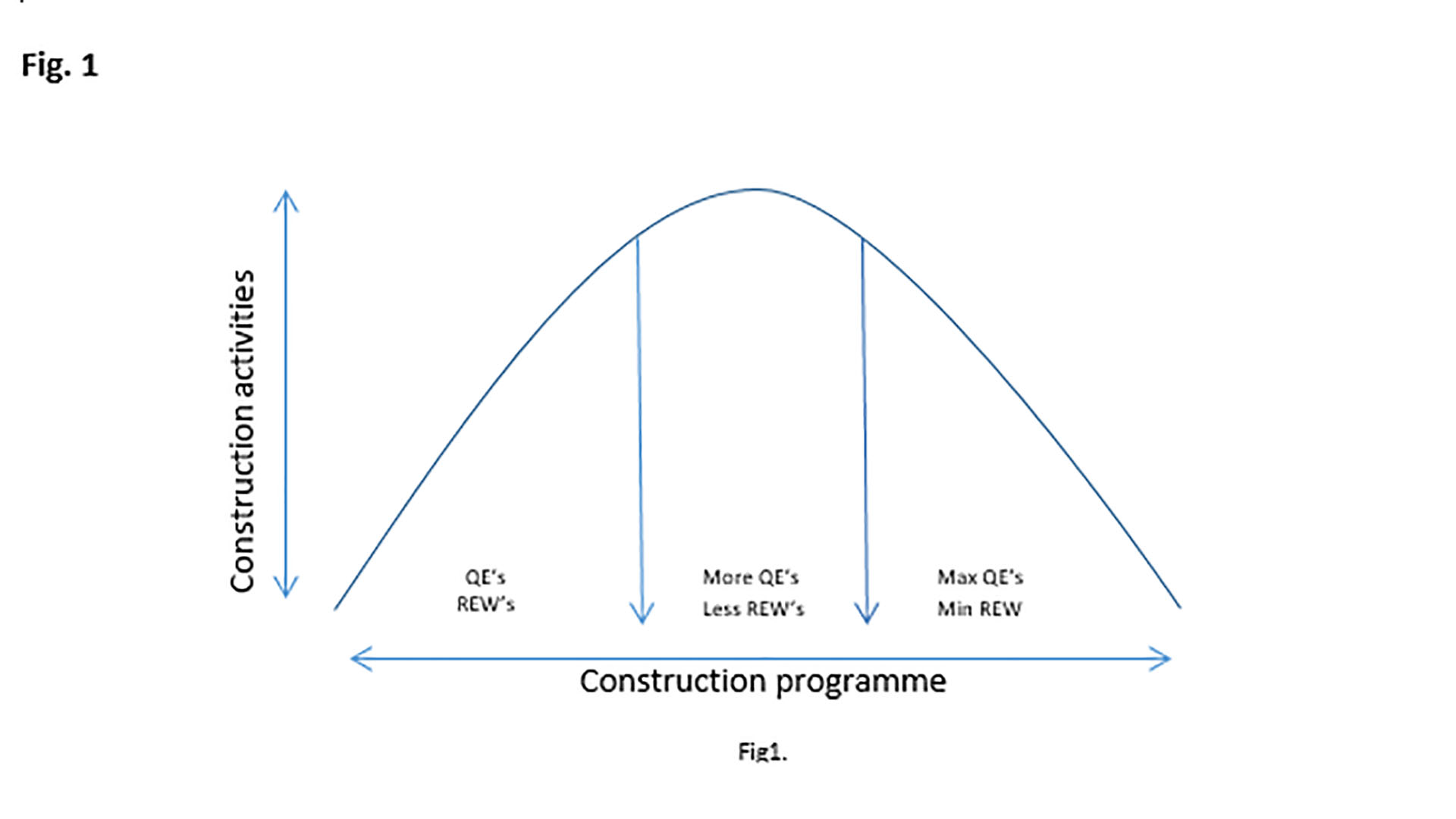

Each project has certain labour profile characteristics, that are determined by the programme of work and the assessed degree of required technical complexity. For example, the fit out and connection of a nurse call bedhead system would require a high proportion of Qualified Electricians (QE’s) to safely connect and commission this type of installation. Whereas, a street lighting installation, will feature more manual and less technical work which would allow for an increased use of Restricted Electrical Workers (REW’s).

Hospitals, schools and factories are typical of projects that are complex as they tend to include extensive levels of design, related systems, coordination with others and diversity of technical materials.

Industrial and commercial electrical installation work, especially on new projects, commences with first fix work. Completion of the building shell provides installers with the opportunity to fix primary support brackets and drops for cable containment systems, including, basket, tray, ladder and trunking.

The UK electrical industry relies on the use of REW’s to help install enabling work associated with the first fix activity. Such activities include drilling masonry holes, fitting brackets and rod drops, connecting and erecting linear lengths of containment systems.

Attention must be given to the safe working load capacity, installation method and spacing of the selected fixing products by those undertaking first fix tasks. Compliance with the containment manufacturers recommended mechanical and electrical assembly requirements must also feature in the on-site quality control assessments. Therefore, the installation of electrical first fix work should always be supervised and inspected by a QE licence holder.

The skills required by REW’s to carry out or assist with first fix work must be evaluated and matched to the requirement of the planned work. Many REW’s possess comparable skills with a Qualified Electrician in first fix containment work. However, the local industry entry criteria for a REW licence only requires two years relevant minimum industry experience. Contract managers should consider the potential implications of the minimum criterion, when evaluating those engaged in first fix activity, especially where there is a high proportion of REW’s.

Employing REW’s to carry out first fix work on projects is necessary for several reasons –

The illustration provided in Fig 1. is for guidance purposes only and must not be considered prescriptive. Tidy, bell curve pathways are seldom, if ever, experienced in the construction industry. The employment and ratio of Restricted Electrical Workers to Qualified Electricians must be determined by the requirements of each specific project.

Reliance on a high ratio of Restricted Electrical Workers to Qualified Electricians throughout a construction programme has the potential to affect the quality and integrity of unseen first fix work.

The development of the UK electrical contracting industry is best served through the recruitment and training of apprentices and upskilling of existing workers. Public procurement policy, community needs, and public interest are also more likely to be met where priority is given to the employment of apprentices.